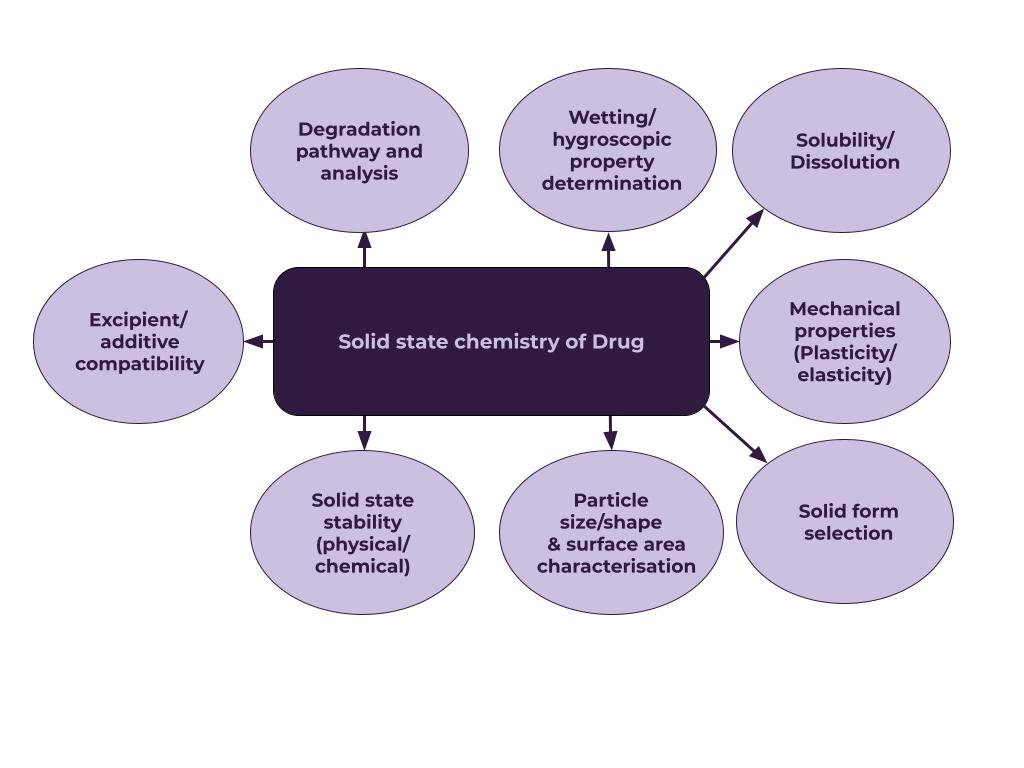

Solid-state Analysis

Are you looking to

- Select a stable, robust, and reproducible drug product?

- Mitigate development risks?

- Set adequate acceptance limits for quality specifications?

Select the stable form as soon as possible and study all-solid-state properties.

Monitor properties of each batch.

For particle/powder analysis, we can offer:

- Examination of particles sizes

- Particle morphology by optical and scanning electron microscopy

- Specific and outer surface area

- Porosity

- Hygroscopicity

- Crystallinity, polymorphic purity

- Thermal properties: melting point, glass transition, heat capacity, sublimation etc.

- Dissolution rate

- Stability

- Density, including bulk and tapped density

- Single-crystal structure determination (non-GMP)

- IR spectra for identification and imaging

- Raman spectroscopy

- Other – please ask