Laser Diffraction

Laser diffraction is used for the determination of particle size distribution

Laser diffraction is used for the determination of particle size distribution (PSD).

The particle size distribution measured by laser diffraction is helpful for:

- Detection of batch-to-batch variations

- Test the influence of production changes on the particles

- Study if the PSD is a critical quality attribute for the manufacturing process

- Investigate the effect of PSD on dissolution and bioavailability

- Investigation of PSD stability during shelf life

- Detection of agglomerates and study the strength of agglomerates

- The PSD will always be the utmost critical attribute for the dry powder inhalation (DPI) products

- Control the content uniformity of formulations, especially for the low drug load formulations

For Material Experts:

Instrument and measuring principle, laser diffraction

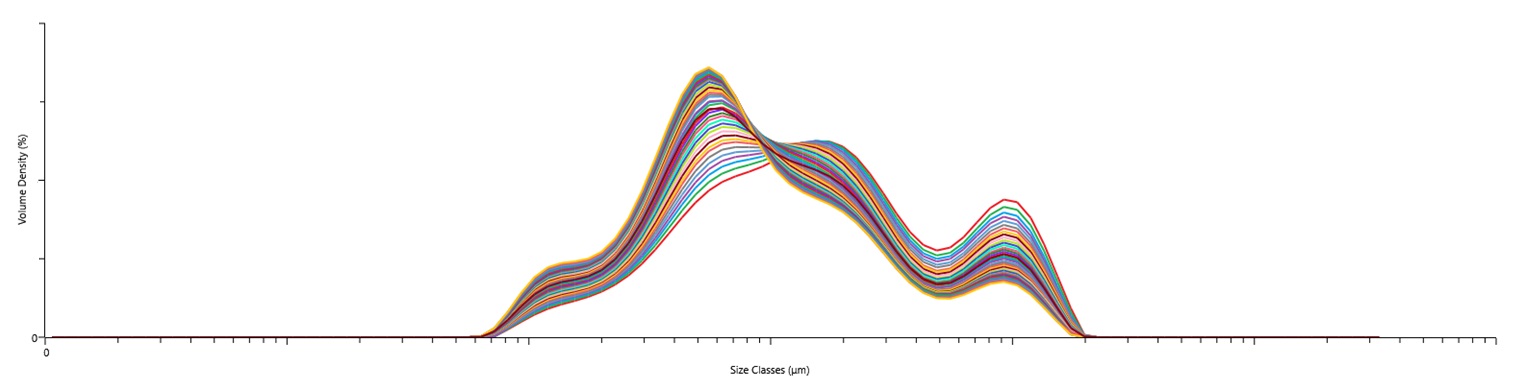

By laser diffraction analysis, it is possible to measure particles sizes between 0.01 and 3500 µm. The sample is dispersed in either air or a suitable liquid media. The laser passes through the dispersion media and is diffracted by the particles. The diffraction light pattern (He-Ne & Krypton laser) is dependent on the particle size. The laser diffraction pattern is measured and correlated to the particle size distribution based on Fraunhofer or Mie theory. The use of Mie theory presupposes knowledge of the light refractive index of the particles and the dispersion media and the imaginary part of the refractive index of the particles. Particle Analytical can determine these refractive index parameters.

The laser diffraction instrument applied by Particle Analytical (Malvern Mastersizer 3000 and 2000) has a flow-through cell for dispersion of particles in liquid media or a dry dispenser for dispersion of particles in the air. Wet dispersion presupposes that the particles are insoluble in the liquid. Therefore method development is required. We typically offer either a simple non-GMP suitability screening or a full-length GMP method development.

| Instruments | Malvern Mastersizer 2000, 3000 |

| USP/Ph. Eur. | USP 429/Ph. Eur. 2.9.31 |

| Dispersion units | Hydro2000SM, Hydro2000S and Scirocco2000 from Malvern, HydroMV, Aero |

| Dispersion media | Liquid or air |

| Parameters | Sonication, stirring speed (liquid) feeding rate, pressure (air) |

| Measuring range | 0.01-3500, 0.02- 2000 µm (liquid) 0.1-3500, 0.1-2000 µm (air) |

| Sample amount | 10-500 mg (liquid) 0.5-10 g (air) |

Literature

Adjei A, Garren J (1990) Pulmonary delivery of peptide drugs: effect of particle size on the bioavailability of leuprolide acetate in healthy male volunteers. Pharm Res (6):565-9.

Barber D, Keuter J, Kravig K. A logical stepwise approach to laser diffraction particle size distribution analysis methods development and validation. Pharmaceutical development and technology. 1998 Jan 1;3(2):153-61.

Buanz A (2021) Powder characterisation. In The Science and Practice of Pharmacy, ed. Adejare A, Remington: 295-305.

Kumar R, Thakur AK, Chaudhari P, Banerjee N ( 2021) Particle Size Reduction Techniques of Pharmaceutical Compounds for the Enhancement of Their Dissolution Rate, and Bioavailability. J Pharm Inno 11:1-20.

Provder T. Challenges in particle size distribution measurement past, present and for the 21st century. Progress in organic coatings. 1997 Dec 1;32(1-4):143-53.sperser. Int J Pharm 501(1-2):65-74.