Measure Particle Size

Laser diffraction is our primary choice for Particle Size Distribution measurements, and we have world-class expertise in performing this analysis and developing the method.

The method is developed to fit the challenge at hand, which depends on the dissolution, robustness, flowability and bioavailability of the pharmaceutical dosage forms such as dry powder inhalation products, tablets, capsules, emulsions, suspensions etc.

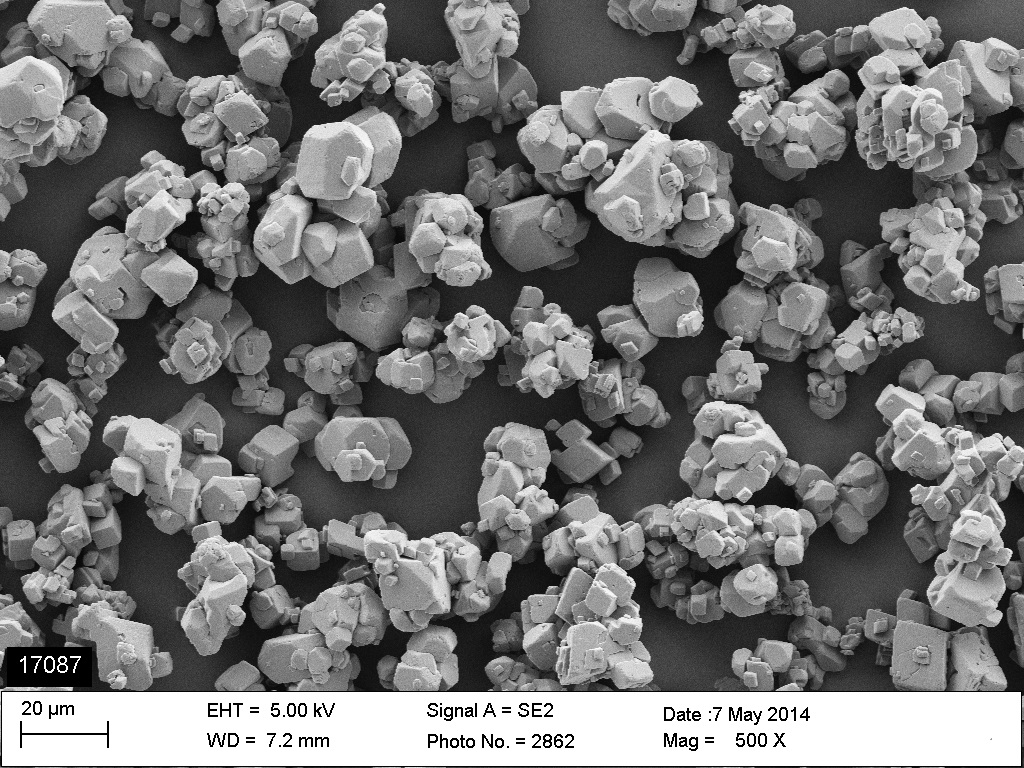

Measure Morphology

Morphology provides a static description of your powder, enabling a greater understanding of both sample and process. Investigate challenging applications and automated QC analysis where robust, user-independent results and validation are required.

If the method needs to be validated for QC during drug development and manufacturing read more about validation.