Method Development

Are you always sure that the analytical (standard) method can give you adequate results when ordering individual analysis?

The optimisation of a method during the manufacturing process development is frequently needed to fit the systematically chosen Quality-By-Design (QbD).

Did you know that

- Most standard methods have exceptions

- Frequently material properties impact the results or even make a method irrelevant

- It saves time and money to adopt standard methods to fit each case

Particle analytical has +20 years of expertise in method adoption and development!

More Information

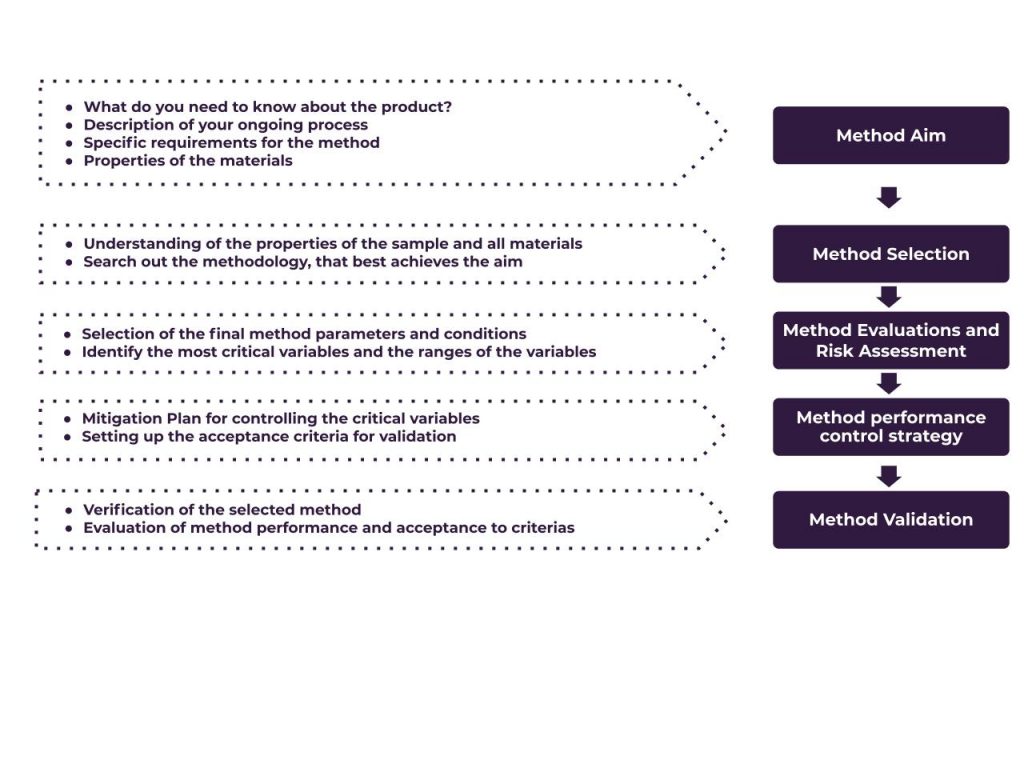

This is an example of a method development process:

- Setting the aim of the method

- Searching for the optimal analytical parameters to achieve the goal

- Study the properties of the material – we define the package in collaboration with you

- Finding the optimal measurement parameters, i.e. measurement time per step, equilibration conditions, pre-drying time, dispersion media and time etc.

- Comparing the method under development with the existing methods

- Evaluating the critical method variables

- Evaluation of method robustness

- Building strategy of risk mitigation

Example of possible Method Development Strategy. The Scheme adopted from Vogt FG, Kord AS (2011).