- Are you in a deadlock with the particle size distribution analysis or method?

- Have you obtained the FDA warning letter considering particle size distribution issues?

- Do you need to study how particle size distribution affect the bioavailability and dissolution of your new drug candidate?

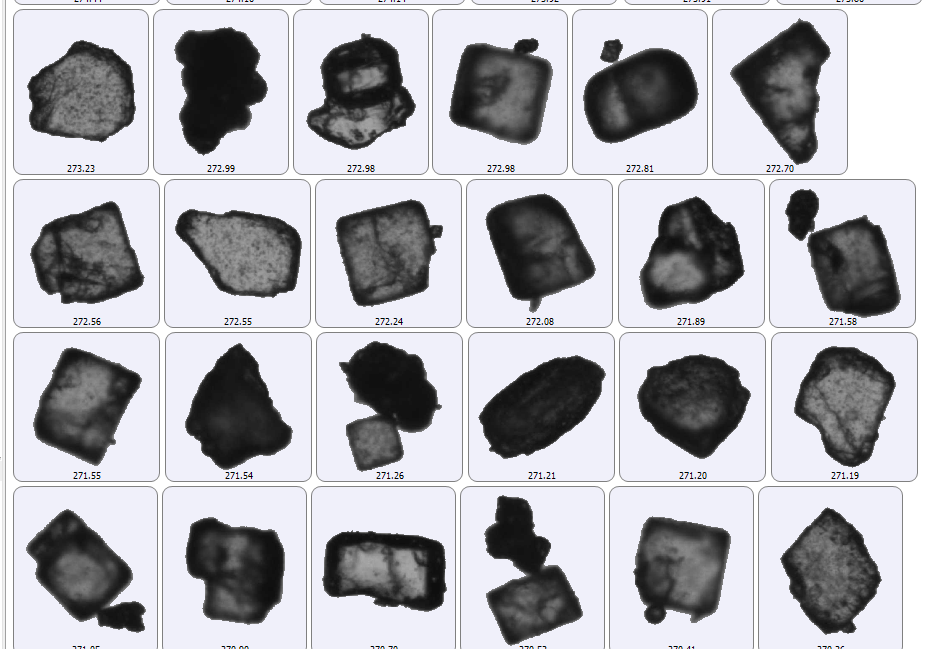

Particle size is by far the most important physical property of particulate samples. Particle size determinations are routinely carried out across a wide range of industries and are often a critical quality attribute in the manufacture of many products.

We help you to plan the studies showing the effect of particle size distribution on your product performance

We will do a Method development measuring the Particle Size Distribution of your product.

You can also read more on Particle Size & Morphology, Surface Area and Dissolution rate measurements.