Dynamic Vapor Sorption (DVS)

Dynamic vapour sorption (DVS) is a gravimetric technique that measures how quickly and how much of a solvent is absorbed by a sample, such as a dry powder absorbing water. The water uptake describes how hygroscopic the compound is. Hygroscopicity is highly relevant in the evaluation of storage conditions and general stability, as “water-containing”/hygroscopic compounds might be quite unstable. Water or solvent vapour might cause:

- Formation of hydrates/solvates

- Transformation of the crystalline form

- Increased reaction rates, i.e. degradation of the pharmaceutical compound.

- Disproportionation of pharmaceutical salts or dissociation of cocrystal

- Decrease the glass transition temperature and induce crystallisation of amorphous material or amorphous solid dispersion

- Deliquescence

DVS is primarily used to:

- Evaluate the hygroscopicity of drug substance powder. This property is used to evaluate the developability of new drug candidates and must be determined in the preformulation stage.

- Compare the hygroscopicity of different solid-state forms: polymorphs, solvates, salts, cocrystals, amorphous

- Determine the deliquescence point of material

- Quantify and qualify the amorphous content in drug substance or excipient

- Specific surface area determination

- Compatibility studies

- Evaluate the moisture sorption-desorption behaviour of granules, capsule formulations, tablets

- Measure the diffusion and permeability of packaging materials, for instance, blisters

- Predict the stability of micronised material during shelf-life

- Study polymorphic transitions induced by moisture or solvent vapours, especially solvate and hydrate formation

- Study drying and dehydration behaviour of powders

- Observe changes in a sample appearance due to humidity

A standard dynamic vapour sorption measurement analysis is determined at relevant temperatures. The method complies with Ph. Eur. 2.9.39

For Material Experts:

Instrument and measuring principle, DVS

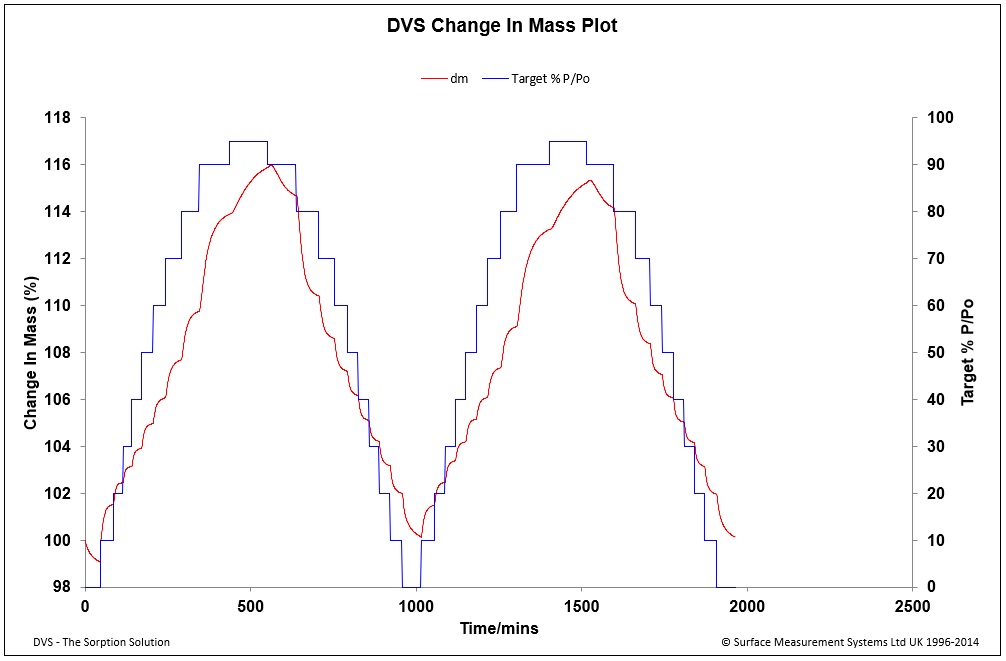

In a dynamic vapour sorption measurement, the water concentration surrounding the sample is varied and the change in mass which this produces is measured. The DVS analyser is based on a vertical nulling microbalance in which the sample and a reference hang-down wire are enclosed in a humidity- and temperature-controlled chamber. The humidity is controlled by a dry nitrogen purge steam between a dry- and a wet line (saturated with water). A high precision mass flow controller regulates the proportion of wet and dry gas to obtain the desired humidity.

In a standard set-up, the humidity is increased from low to high humidities. As desorption might take place at a different rate, the humidity is following decreased to low humidity while measuring the weight loss. Furthermore, a second run is performed in order to see whether the material’s structure or behaviour are changed due to the initial exposure to high humidity. The Dynamic Vapor Sorption Instrument applied by Particle Analytical is a DVS Advantage 1 from Surface Measurement Systems.

| Instrument | DVS Advantage 1 from Surface Measurement Systems |

| USP/Ph. Eur. | Ph. Eur 2.9.39 non GMP |

| Humidity range | 0-98 % relative humidity |

| Temperatures | 5 to 60 °C |

| Sample amount | 10-20 mg |

Literature

Airaksinen S, Karjalainen M, Shevchenko A, Westermarck S, Leppänen E, Rantanen J, Yliruusi J (2005) Role of water in the physical stability of solid dosage formulations. J Pharm Sci 94(10):2147-2165

Argyropoulos D, Alex R, Kohler R, Müller J (2012 ) Moisture sorption isotherms and isosteric heat of sorption of leaves and stems of lemon balm (Melissa officinalis L.) established by dynamic vapor sorption. LWT. 47(2):324-31.

Barham AS, Tewes F, Healy AM (2015) Moisture diffusion and permeability characteristics of hydroxypropylmethylcellulose and hard gelatin capsules. Int J Pharm 478(2):796-803

Burnett D, Garcia AR, Naderi M, Acharya M. Moisture Sorption Properties of Pharmaceutical Materials Studied by DVS. DVS Application Note.

Driemeier C, Mendes FM, Oliveira MM. Dynamic vapor sorption and thermoporometry to probe water in celluloses. Cellulose. 2012 Aug;19(4):1051-63.

Duralliu A, Matejtschuk P, Williams DR (2018) Humidity induced collapse in freeze dried cakes: a direct visualisation study using DVS. Eur J Pharm Biopharm 127:29-36.

Heljo VP, Sainio J, Shevchenko A, Kivikero N, Lakio S, Juppo AM (2013) The effect of relative humidity on the physical properties of two melibiose monohydrate batches with differing particle size distributions and surface properties. J Pharm Sci 102(1):195-203

Khoo J, Garcia AR, Burnett D, Abdalghafor H, Lane ME, Van Vlierberghe S, dos Santos A, Boterberg V, Dubruel P (2011) Vapour permeability of porous materials using Payne diffusion cell. DVS Application Note.

Khoo JY, Williams DR, Heng JY (2010) Dehydration kinetics of pharmaceutical hydrate: effects of environmental conditions and crystal forms. Dry Technol 28(10):1164-1169.

Löbmann K, Flouda K, Qiu D, Tsolakou T, Wang W, & Rades T (2014) The influence of pressure on the intrinsic dissolution rate of amorphous indomethacin. Pharmaceutics 6(3): 481-493

Rumondor AC, Taylor LS (2010 ) Effect of polymer hygroscopicity on the phase behavior of amorphous solid dispersions in the presence of moisture. Mol Pharm 7(2):477-90.

Sheokand S, Modi SR, Bansal AK (2014) Dynamic vapor sorption as a tool for characterisation and quantification of amorphous content in predominantly crystalline materials. J Pharm Sci 103(11):3364-3376

Shevchenko A, Din Belle D, Tiittanen S et al. (2011) Coupling Polymorphism/Solvatomorphism and Physical Stability Evaluation with Early Salt Synthesis Optimization of an Investigational Drug. Org Proc R & D 15 (3): 666-672

Young PM, Chiou H, Tee T, Traini D, Chan HK, Thielmann F, Burnett D (2007) The use of organic vapour sorption to determine low levels of amorphous content in processed pharmaceutical powders. Drug Dev Ind Pharm 33(1):91-97